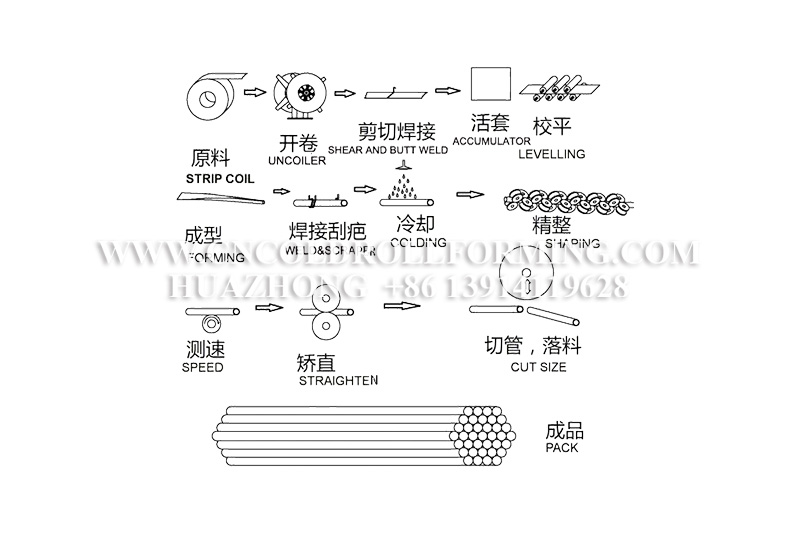

Uncoiler

Composition: manual expansion, pneumatic expansion and hydraulic expansion, single and double drum;

Braking: pneumatic break;

Work station: manually and rotation;

Function: take coils form overhead crane, de-coil and feed coils onto production line;

Operation: use manual, cylinder or hydraulic expansion the coil on the uncoiler, and release the strips.

Shearing and welding machine

Composition: pneumatic or hydraulic cutting and welding (automatic or manual);

Steel centering: by manual;

Function: to butt weld strips end together;

Construction: strips centering device, shearing device, welding device, moving rack device, pneumatic or hydraulic system.

Horizontal accumulator

Composition: turning stands, pinching motor, loop body and center unloader etc.

Function: feed the steel strips into the accumulator in advance, to allow sufficient time for welding of steel strips and ensure continuous operation of the machine.

Vertical cage

Construction: lron sheet and profiled steel etc welded structure;

Function: feeding material to cage through the feeding motor.

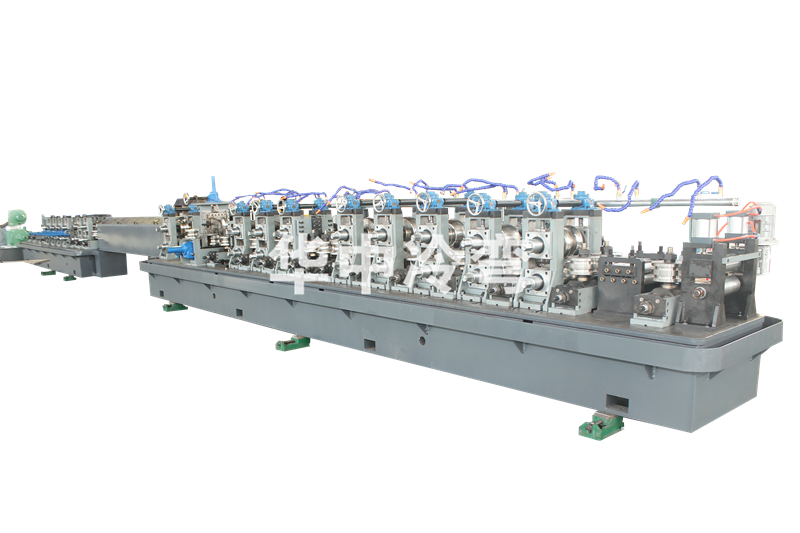

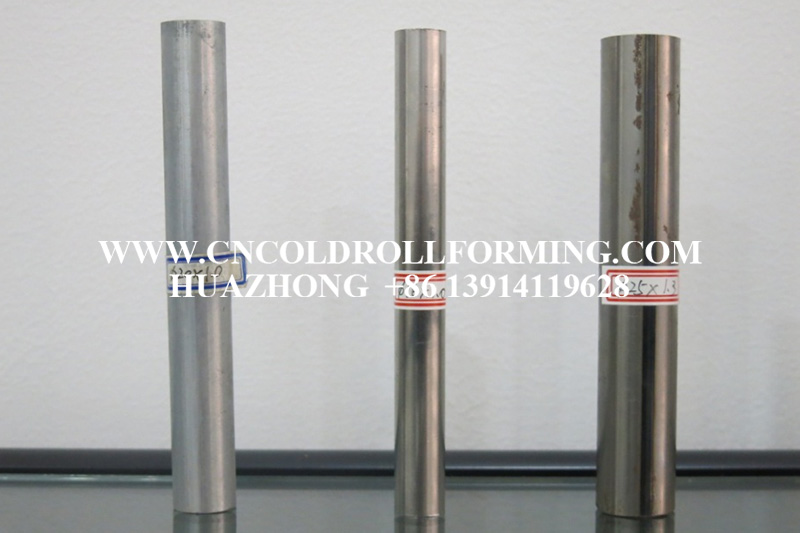

Main machine, forming and sizing

Function: every stands rolling the strips to tube step by step, and sizing machine controlled the finish precision size and roundness

Construction: each group of rollers consisting of upper rollers and bottom rollers which driven by DC motor connecting to universal shaft and gear box, roller equippsd on the shaft, centering by spacers. Stands made by cast iron;

Operation: the steel strip pass through each upper rollers and bottom of each stands which driven by motor of gear box. Operators may replace these rollers by unload the bolts and pull out the stands;

Function of vertical roller: double sides forming group of rollers hold the steel strips in right forming and avoid the strips bouncing back;

Construction: vertical shaft installed on the base with bearing house.

Cold saw

Function: sized cutting free of burs;

Composition: it’s a unit equipped with clamping device, saw cutting car on a steel structure, linear guide rail and gear wheel driven by simens servo motor, which can complete cutting free of burs;

Operation: there are three modes of control, e.g. manual control, simulation control and automatic control, with man-machine interface allowing the operators to operate to monitor the system and set system parameters as well.