- Home

- About Us

- Products

- Roller Shutter Machine Series

- Garage Door Machine Series

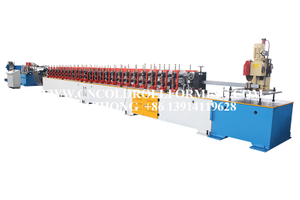

- Struct Channel Roll Forming Machine

- Upright Beam for Shelves Roll Forming Machine

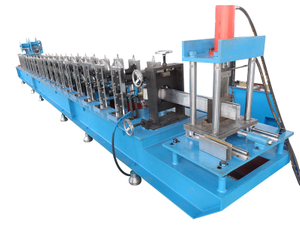

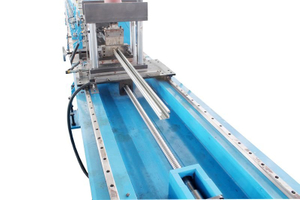

- C/U/Z Profile Roll Forming Machine

- LGS Roll Forming Machine

- Door/Window Frame Machine

- Tube Forming Line

- Decorative Panel Line&Sandwich Panel Line

- Corrugated Machine

- Customized Profile Roll Forming Machine

- Profile

- Case

- Brochures

- FAQ

- Contact Us